About Us

Maxield Bearings is an emerging manufacturer of white metal-lined hydrodynamic bearings, known for precision, quality, and reliability. Established in 2007 by Mr. MKC Appa Rao, a former Indian Air Force personnel, Maxield embodies a disciplined, precision-driven approach to manufacturing.

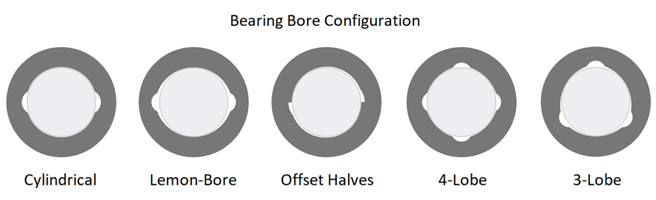

We specialize in producing white metal bearings for steam turbines, gas turbines, and pumps, serving major companies in India and internationally through strategic partnerships. Our expertise includes manufacturing bearings for gearboxes, offset bearings, and two-lobe, three-lobe, and four-lobe configurations. Additionally, we supply bearings for marine projects, sugar mills, cement industries, steel industries and various other industries wherever there is a requirement, offering flexibility to meet diverse customer needs.

At Maxield, we adhere strictly to OEM-supplied drawings, ensuring compliance with the highest quality standards and rigorous inspections, guaranteeing superior performance and timely delivery at competitive pricing.

An ISO 9001:2015 Certified Company

A Closer Look at Our Expertise

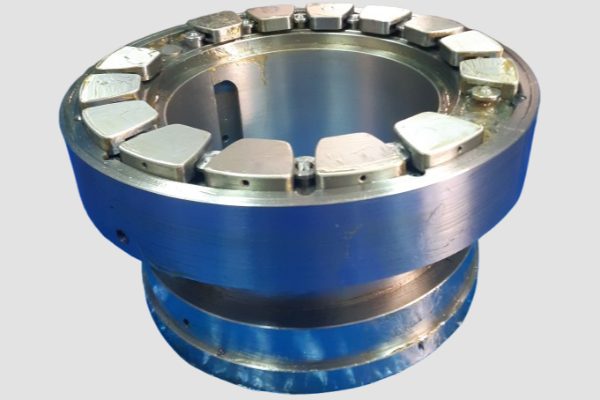

A Glimpse of some our precision-engineered bearings

Journal Bearing Type 1

Journal Bearing Type 2

Journal Bearing Type 2

Four Lobe Thrust Bearing

Single Side Thrust Bearing

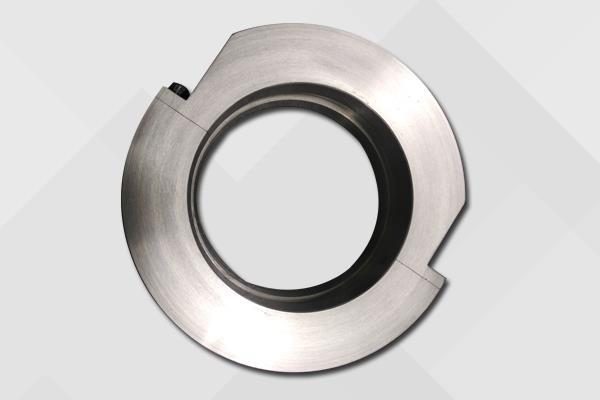

Offset Bore

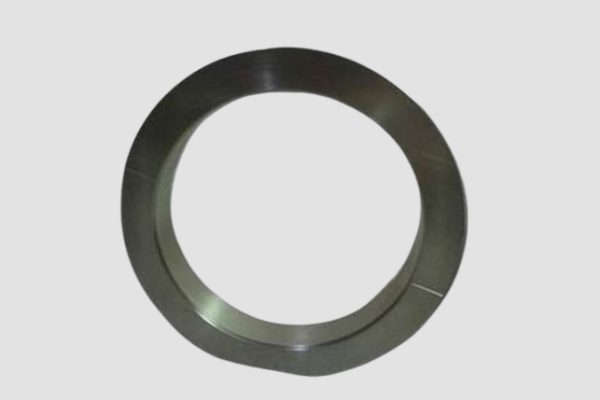

Thin Wall Bearing

Special Bearing

Oil Seal

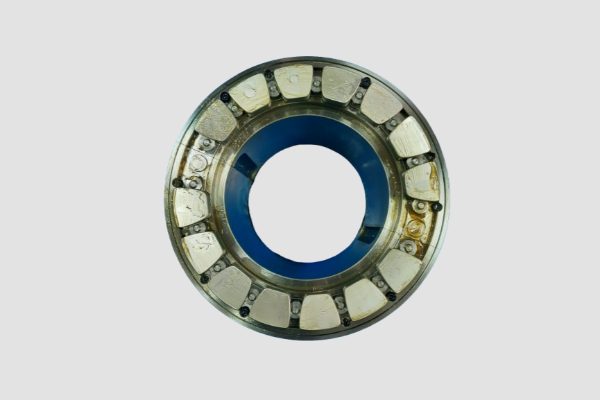

Inner Titling Pad Bearing

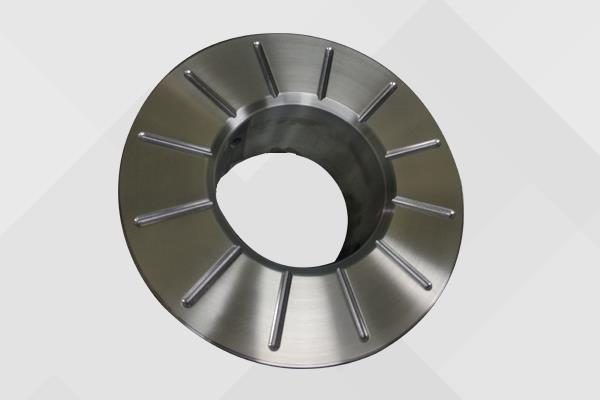

Thrust Pad Bearing

Thrust Pad Bearing

Oil Inlet Fittings

Oil Feed Connectors

Our Mission

Maxield Bearings mission is to be Globally Competitive through Customer – Oriented approach and by achieving Excellence through Quality, Service, Innovation and Technology.

Material Quality & Testing

Maxield Bearings adheres to ISO 9001:2015 for a structured and efficient Quality Management System (QMS), ensuring consistency, traceability, and continuous improvement across all processes.

Material Quality & Testing

We conduct thorough material inspections and testing to guarantee superior raw material integrity:

- Batch-Wise Lab Testing– Every batch of raw material is tested in a certified lab to ensure compliance with required specifications.

- Ultrasonic Testing (UT) of Backing Material– Performed upon receipt from the supplier as per ASTM SA388 standard, ensuring defect-free material.

- Babbitt Bonding Integrity Testing– Conducted following ISO 4386/1 Class 3 reference standard, with ISO 4386/1 Class A as the acceptance criteria.

- Dye Penetrant Test (DPT)– Carried out according to ISO 4386-3 Class A reference standard, with acceptance criteria as per ISO 4386-3 Class A.

Our strict adherence to quality protocols ensures that every bearing meets the highest industrial benchmarks for performance, durability, and safety.

Commitment Beyond Delivery: After-Sales Service

At Maxield Bearings, our responsibility doesn’t end with delivering the product—it extends to ensuring its long-term performance and reliability. We stand by the quality and integrity of our bearings, which is why we offer:

- 18-Month Guarantee– Every bearing comes with an 18-month warranty, backed by comprehensive reports to ensure full transparency and confidence in our product.

- Full Responsibility for Quality– If any issue arises due to our compromise in material or manufacturing, we take full responsibility and provide the necessary support to resolve it.

- Customer-Specified Packaging– We understand the importance of safe handling, so we pack bearings exactly as per customer instructions, ensuring they arrive in perfect condition and ready for use.

- Continuous Support & Feedback – We value customer feedback and are always ready to make improvements, ensuring a seamless experience from production to installation and beyond.

We also manufacture the following bore configurations

Our Strengths

- Proper Tests are conducted while boding of White metal Bonding of white Metal Lining. Our Products to ensure Good Bonding

- We provide you with customized products to suit you requirements.

- Best vendor award received from our major customer m/s Triveni Engineering and Industries Ltd, Mysore consecutively since last five years in quality, timely delivery & price.

Applications

Marine

Marine

Gear Boxes

Gear Boxes

Pumps

Pumps

Gas & Steam Turbine

Gas & Steam Turbine

Cement & Steel Industry

Cement & Steel Industry

Some of Our Major Clients